Lake Spofford Ice Harvest

Before mechanized refrigeration, as January turned to February, talk in New Hampshire's communities centered around the thickness of ice on local ponds and lakes. It was time to fill the icehouses for the coming year! Although some families had their own ice ponds, Lake Spofford was the main ice source for much of the town, its many smaller inns, and for the Pine Grove Springs Hotel. Although there were many icehouses around the lake, the hotel had the largest and tallest one in town.

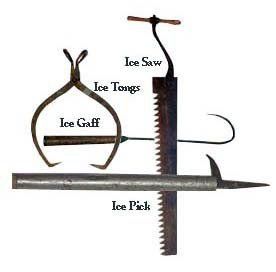

The ice cutting process began by determining when and where to harvest. The ice thickness was measured by drilling a hole with an ice auger and inserting a metal ruler with a end hook that would grab the ice's bottom. By reading the measurement at the surface, the ice thickness was determined. This process was completed in multiple locations. Because weather played a major role, "where" was far easier to solve than "when". It was best done in clear and cold conditions. Once when the weather looked favorable, an ice cutter joked that it was perfect because "It's so cold this morning, I put on two pairs of suspenders."

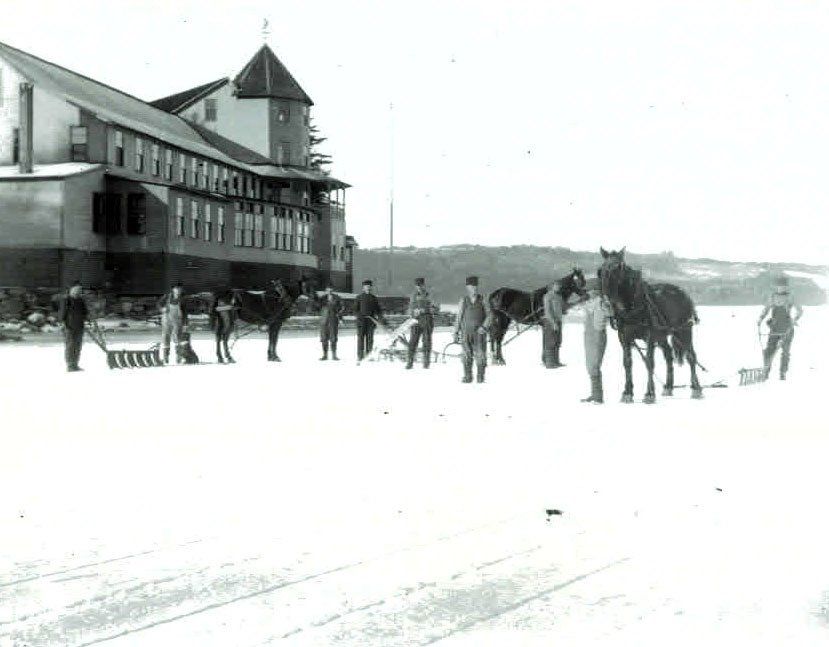

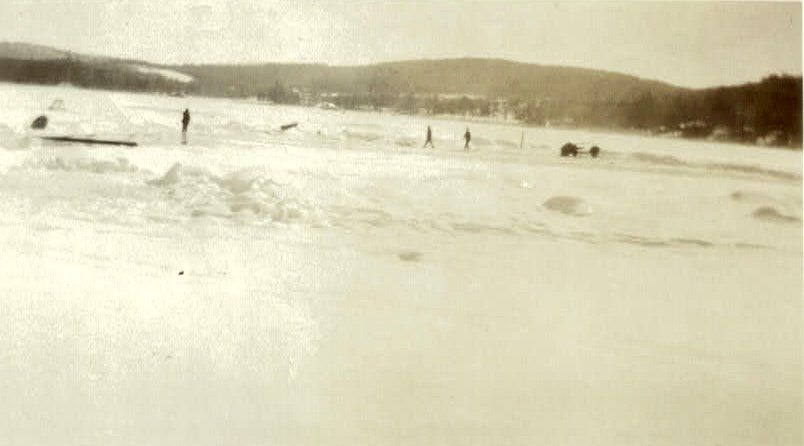

Once the ice reached 8" – 18” deep and the weather was cooperating, the snow cover was removed by hand or with a horse drawn plow.

The exposed ice was then marked off into grids, usually 22”X32” to 44” square. The lines were scored using a hand scorer or one pulled by a horse (above). The scoring could not be more than 2/3 the thickness of the ice, otherwise there was a danger of the horse falling in.

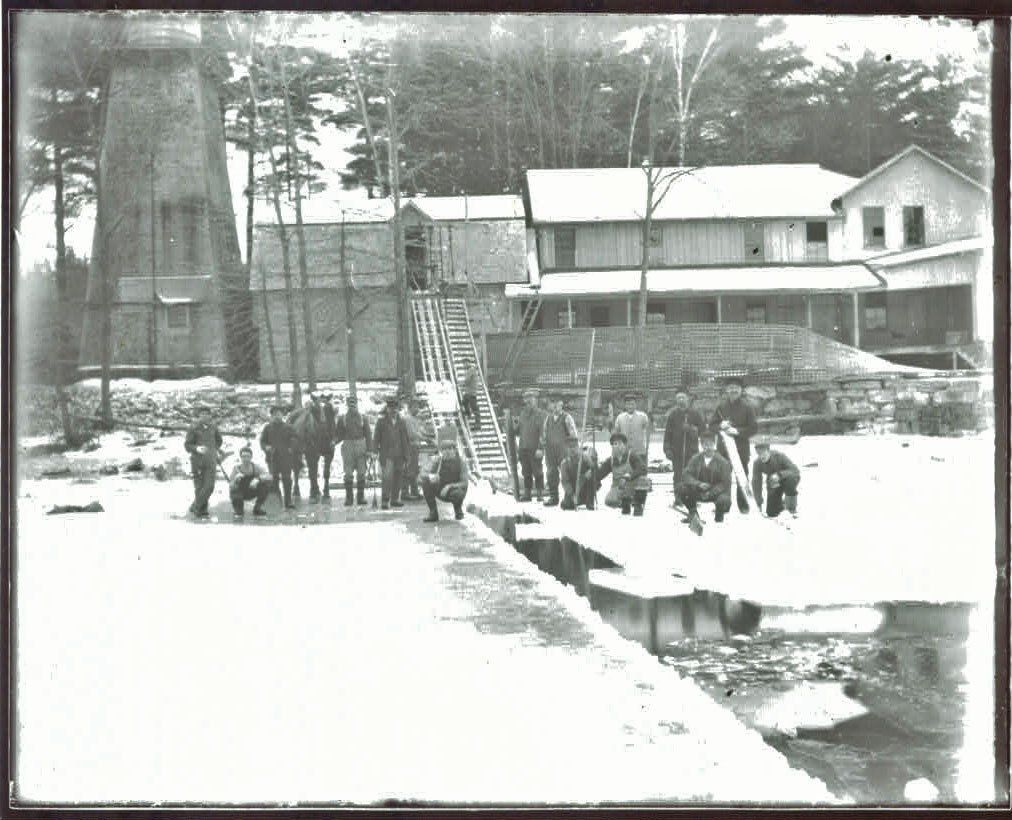

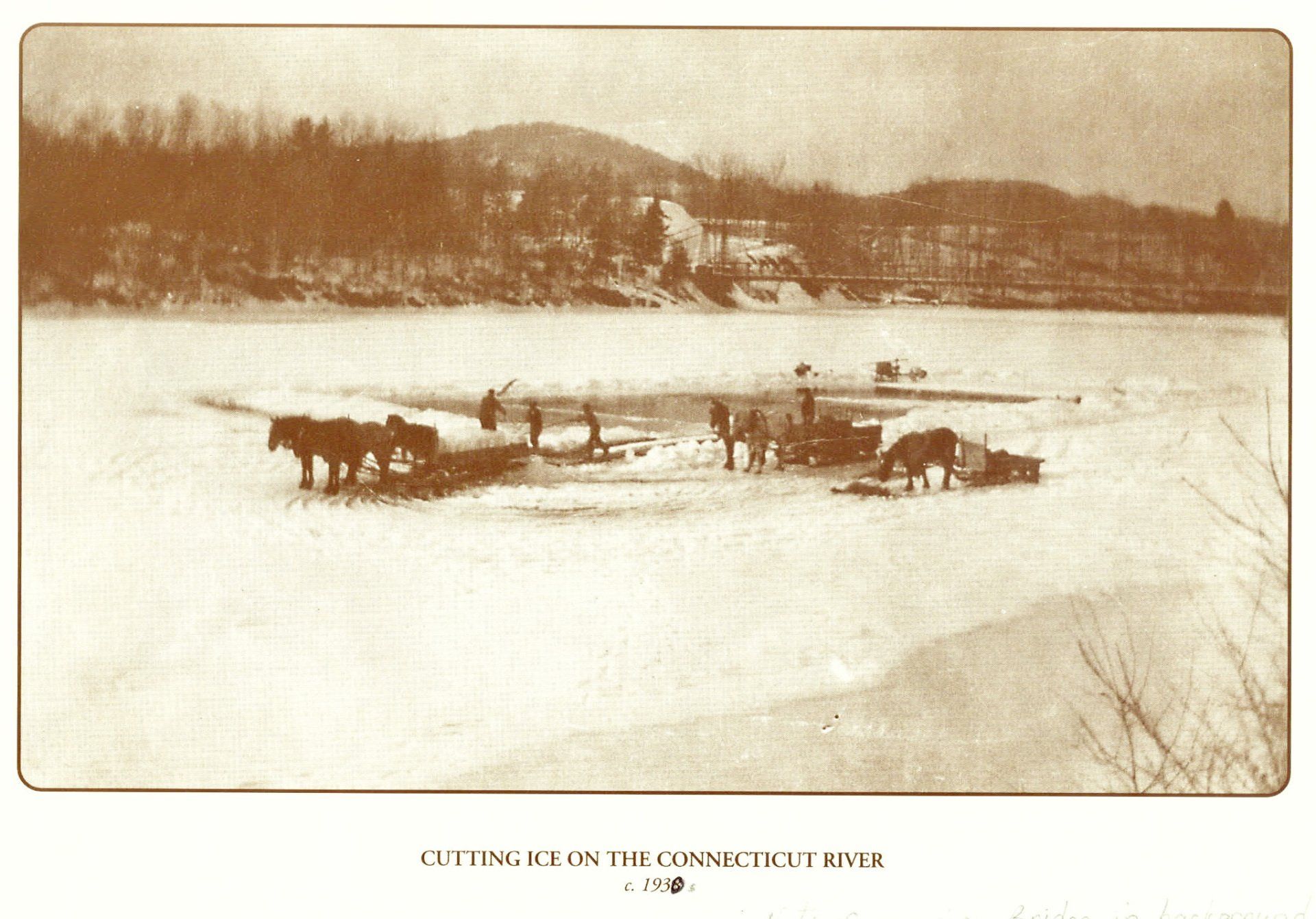

Sawing along the lines came next. The cutters used long-handled ice saws. They did not need to cut out each individual block; it was faster to cut out a line of several blocks called rafts. Using a ice pick (as long as 16'), they floated the rafts down a channel to the loading point. A heavy chisel called a breaking-off bar was jammed into the deep grooves between ice blocks, popping them apart.

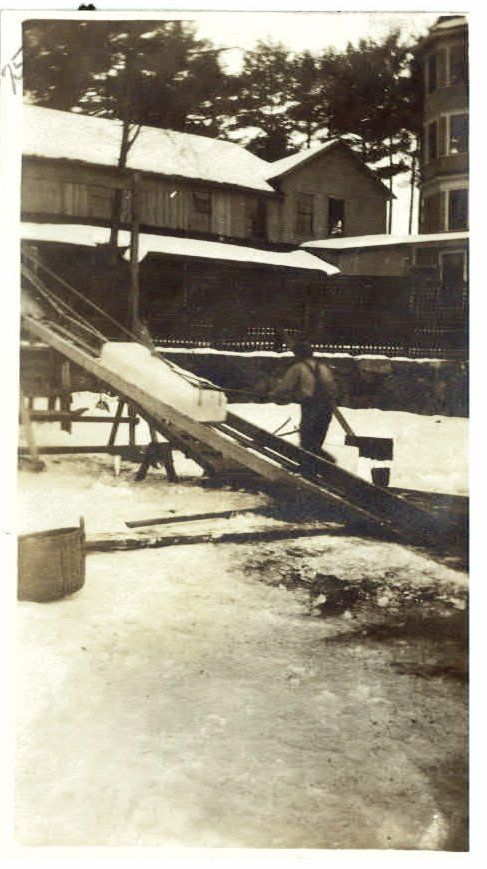

The finished blocks were loaded onto a sled for transport to the icehouse. If lucky, the channel lead directly to the icehouse chute (left - Pine Grove Springs Hotel). The blocks were moved onto the chute with gaff hooks and guided or hoisted into the various levels of the icehouse. There, they were surrounded by layers of insulating sawdust. A well-built icehouse kept ice available well into fall.

Both men and horses needed to keep from slipping on the ice. The horses wore special horseshoes with long cleats. The men wore "creepers", metal plates with short cleats that strapped onto each heel of their boots.

Beginning in the early 1930's, mechanical ice machines gradually took the place of ice harvesting. The cleaner and more sanitary manufactured ice could be produced year-round. However, there are a few places where the traditional art of ice cutting continues. In NH, the "Annual Squaw Lake Ice Harvest " is billed as one of the last "commercial" ice harvesting operations in the world.