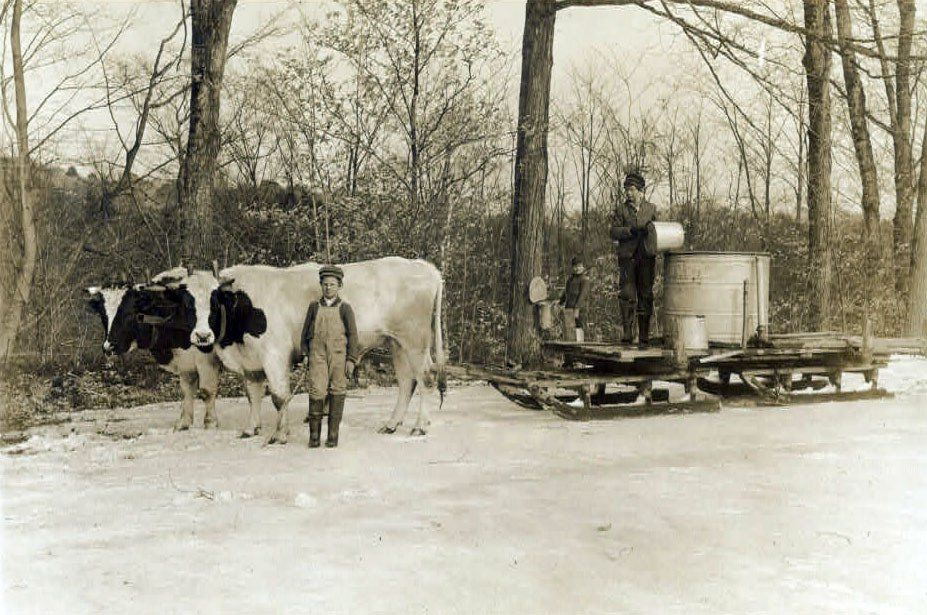

Sugaring Off Season

Think pancakes folks, as the trees will soon be awakening, and the run will begin anew.

(Originally sent 2/22/21)

Sugaring off, or the production of maple syrup, is an ancient tradition. Native Americans gashed trees, collected the sap in wooden troughs or bark bowls. The sap was allowed to partially freeze to concentrate the sugar and was then boiled down by dropping heated stones into the liquid. This produced sugar cakes which were easy to transport and store.

Starting in the 1600s metal kettles made syrup and sugar cakes production easier. Regionally, maple sugar and honey were the primary household sweeteners and valuable trade items. This continued into the 19th Century when molasses became more available.

Weather determines the beginning and end of the sap run. Late winter's shortening darkness begins nature's preparation for the growing season. It causes physiological changes in trees which encourages them to begin converting stored starch into sugar. The "run" is created by freezing and thawing cycles. This causes pressure changes within the tree, thus forcing the sap up and down the trunk and branches. Maple trees’ unique cell structure releases more sugar into the sap and creates a higher interior pressure than most trees. Of the maples, the sugar maple earned its reputation as the “Jewel of the Sugar Bush” because its sap contains 97% water and 3% sugar and minerals.

Modern technology has replaced the iconic lidded bucket with blue, food grade, plastic tubing winding its way downhill through the sugar bush. Vacuum pumps pull the sap to collection tanks. But the sap's quick spoiling nature makes transport to the evaporators time sensitive. Once there, reverse osmosis machines reduce the water content, allowing more efficient and quicker syrup production.

When the Chickering and Hine families were working their sugar bushes on Catsban Brook and in Sargent Pasture, syrup production was smaller and more of an art than a science.

Now health regulations, syrup hydrometers, and established color variances rule the sugar bush. New Hampshire, on average, produces about 90,000 gallons of maple syrup during the fluctuating sugaring off season. In that it takes from 40 – 44 gallons of sap to make one gallon of syrup, that is a lot of trees to tap and sap to collect. But this labor-intensive activity is still an appreciated tradition looked forward to every spring.